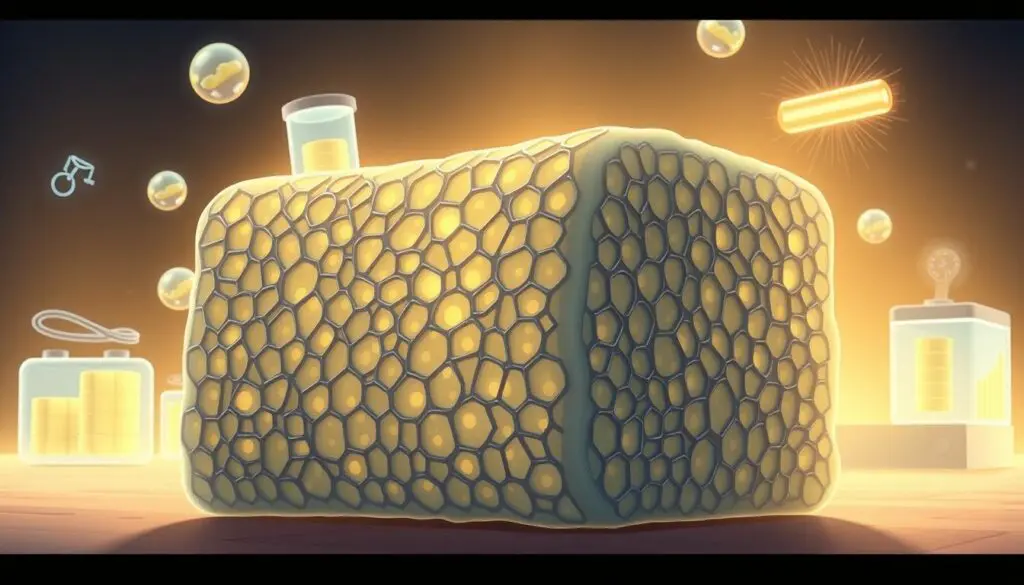

Carbon aerogels are a new innovation in advanced materials. They could change how we store energy. These materials are so light, they are among the lightest things in science1.

They are made from organic gel products. They have a sponge-like structure with lots of air. This makes them very good for storing energy1.

Scientists use special methods to make these materials. They create networks that can change energy technology2. These materials work well in many areas, like supercapacitors and keeping things cool.

Key Takeaways

- Carbon aerogels achieve up to 99.8% porosity

- Extremely low density of 3 mg/cm³

- Specific surface area can reach 2000 m²/g

- Versatile applications in energy storage

- Potential for advanced technological solutions

Introduction to Carbon Aerogels

Carbon aerogels are a new class of super-light materials that have changed materials science. They have amazing properties that make them unique in the world of advanced materials3. With over 95% porosity and pores smaller than 100 nm, they are perfect for many cutting-edge uses3.

Carbon aerogels are incredibly light, with densities as low as 5.7 mg/cm³4. This lightness opens up new possibilities in many fields like energy storage and advanced electronics.

What Are Carbon Aerogels?

Carbon aerogels come from organic materials through special processes. They have a unique structure that gives them amazing qualities:

- Extremely low density

- High surface area

- Exceptional porosity

- Remarkable mechanical properties

Historical Development and Uses

The history of carbon aerogels is filled with important steps. They have shown great promise in areas like:

- Energy storage

- Catalysis

- Chemical sensing

- Electronics

Scientists have made big strides, like creating carbon nanotube aerogels with amazing abilities. For example, some CNT aerogels can hold up to 8000 times their own weight when strengthened3.

| Aerogel Type | Density (mg/cm³) | Key Properties |

|---|---|---|

| Carbon Aerogels | 5.7 | High porosity, low weight |

| CNT Aerogels | 2.3 | High electrical conductivity |

| Graphene Aerogels | 100 | Excellent mechanical strength |

These materials work well from 93K to 773K, showing their wide range of uses4. As research goes on, carbon aerogels will play a bigger role in new technologies.

Properties of Carbon Aerogels

Carbon aerogels are a unique group of materials with amazing features. They have properties that make them useful in many fields in the study of advanced materials.

Key Chemical Composition

Carbon aerogels have a special 3D structure. They are very light and have lots of space inside. This makes them very flexible, with densities as low as 0.25 mg cm−35.

Mechanical Properties Exploration

Carbon aerogels have strong mechanical features, including:

- Compressive strengths from 1 to 10 MPa6

- Porosity levels up to 99.8%6

- Specific surface area between 500-1000 m²/g6

Thermal Conductivity Insights

Carbon aerogels are great at keeping things cool, with a thermal conductivity of 0.014 W/m·K6. This makes them perfect for keeping things cool in many fields.

| Property | Typical Range | Significance |

|---|---|---|

| Density | 0.1-0.5 g/cm³ | Ultralight material |

| Thermal Conductivity | 0.014 W/m·K | Excellent insulation |

| Electrical Conductivity | 10⁻⁶ to 10² S/m | Versatile electrical properties |

The special structure of carbon aerogels comes from their nanoscale design. This design can be controlled during making7. Their unique traits make them great for storing energy, managing heat, and special engineering uses.

Types of Carbon Aerogels

Carbon aerogels are advanced materials with special properties. They are lightweight and highly porous. This makes them important in both research and manufacturing8.

We look at two main types of carbon aerogels. They show amazing qualities in material science:

Resorcinol-Formaldehyde Aerogels

Resorcinol-Formaldehyde (RF) aerogels stand out. They have:

- Extremely high surface area8

- Controllable pore structure

- Exceptional performance in energy storage applications9

Polyacrylonitrile Aerogels

Polyacrylonitrile (PAN) aerogels have unique mechanical properties. They offer:

- High carbon yield

- Superior structural integrity

- Excellent potential in advanced carbon material development8

| Property | RF Aerogels | PAN Aerogels |

|---|---|---|

| Density | 0.25 mg cm−38 | 0.35 mg cm−38 |

| Porosity | 99.989%8 | 99.5%8 |

| Thermal Conductivity | 24 mW m−1 K−18 | 28 mW m−1 K−18 |

Both RF and PAN aerogels have great potential. They are used in many advanced material applications. This includes energy storage and thermal insulation9.

Manufacturing Process of Carbon Aerogels

Creating carbon aerogels is a complex scientific process. It turns simple materials into ultra-light, advanced structures using precise techniques.

Precursor Materials Selection

The first step is choosing the right materials. Scientists often use organic compounds like:

- Resorcinol

- Formaldehyde

- Polyacrylonitrile

These materials are key to the aerogel’s properties10. The mix is usually between 1:1 and 1:2, helping the structure form well10.

Sol-Gel Process

The sol-gel process turns liquid into a gel-like network. This stage is crucial for creating a solid structure from a liquid. Scientists can adjust many factors to shape the aerogel’s final form11.

Advanced Drying Techniques

Drying is a key step in making aerogels. We use special methods to dry the gel without damaging it:

- Supercritical drying

- Freeze-drying

- Ambient pressure drying

Then, the carbonization happens at high temperatures. This is between 800°C to 1200°C, in a controlled environment10. Using CO2 can make the surface area even bigger, over 1000 m²/g10.

The current tech is at Technology Readiness Level (TRL) 4. This shows carbon aerogel making is very promising10.

Our studies show these methods can make uniform structures. These have great potential for use in batteries, wearable tech, and reactors10.

Applications in Energy Storage

Carbon aerogels are a game-changer in energy storage. Innovative research is unlocking their amazing abilities in various energy storage areas12.

Carbon aerogels have unique structures that make them perfect for energy use. They can be up to 99.8% porous and have surfaces as large as 2000 m²/g13. This allows for better energy storage and transfer14.

Supercapacitors: Revolutionizing Electrical Energy Storage

Carbon aerogels are top-notch for supercapacitors, offering high energy and power density. Their structure helps in storing charge well12. Scientists have made special designs to improve ion flow and cut down on energy loss14.

- High surface area for maximum charge storage

- Efficient ion movement through structured pores

- Lightweight and adaptable material properties

Battery Technologies: Enhanced Performance

In batteries, carbon aerogels act as advanced electrodes. They help ions move faster and increase energy density14. Adding special atoms can make them even better at helping with electrical reactions14.

Hydrogen Storage: Innovative Solutions

Carbon aerogels are also great for storing hydrogen. Their structure helps in adsorbing and releasing hydrogen efficiently12. They can be adjusted to fit future hydrogen storage needs12.

The development of carbon aerogels is changing energy storage. They offer sustainable and efficient ways to meet our growing energy needs13.

Advantages of Using Carbon Aerogels

Carbon aerogels are a game-changer in the world of materials. They outperform traditional materials in many ways. This makes them key players in cutting-edge technologies.

These materials are known for their unique properties. They are incredibly light, unlike anything else out there15. With over 99% air, they are both light and strong, showing great promise15.

Lightweight and High Surface Area Advantages

The structure of carbon aerogels leads to amazing performance:

- They have extreme porosity, with a surface area of 1750 m²/g15

- They are much lighter than regular materials

- They also have great mechanical strength

Thermal and Electrical Conductivity

Carbon aerogels are also top-notch in electrical and thermal areas. They’re perfect for storing energy in new ways. Their special features allow for:

- High electrical conductivity

- Great thermal management

- Being used in supercapacitors for fast charging

| Property | Carbon Aerogel Performance | Traditional Materials |

|---|---|---|

| Surface Area | 1750 m²/g15 | 100-500 m²/g |

| Capacitance | 148.6 F/g15 | 50-100 F/g |

| Operational Temperature | –70 °C15 | –20 °C to –40 °C15 |

Carbon aerogels are incredibly versatile. They are changing the game in many advanced fields.

Challenges in Carbon Aerogel Production

Creating carbon aerogels is tough and holds back their use in industry. Our studies show big problems in making them affordable and in large amounts16.

Economic Barriers in Aerogel Research

Making carbon aerogels costs a lot. The materials and methods needed are expensive17. The main money problems are:

- Expensive raw materials

- Processes that use a lot of energy

- Need for special equipment

Scalability Constraints

Scaling up carbon aerogel making is very hard. Industrial-scale manufacturing needs to keep material quality the same as it grows16. There are big issues with scaling up:

- Keeping the structure the same

- Keeping material properties the same

- Finding cheaper ways to make them

“The future of carbon aerogels depends on overcoming current production limitations” – Advanced Materials Research Institute

New ideas are coming in aerogel research. They focus on cheaper materials and better ways to make them17. By solving these problems, scientists hope to make carbon aerogels useful in industry18.

Future Trends in Carbon Aerogels

The world of aerogel research is always changing with new discoveries. Carbon aerogels are becoming key in many fields leading to big tech leaps.

The carbon aerogel market is growing fast, reaching USD 584.78 million in 202119. Scientists are working on new ways to make these materials better.

Innovative Synthesis Techniques

New methods for making carbon aerogels are being developed. These include:

- Biomass-derived precursor development

- Advanced 3D printing techniques

- Graphene oxide integration for better electrical conductivity

Emerging Applications

Carbon aerogels are being used in new ways. They are great for:

- Flexible electronics

- Environmental cleanup

- Storing hydrogen19

The market expects a big jump, with a growth rate of 12.54%19. These materials have huge surface areas, making them perfect for new tech19.

Carbon aerogels are at the forefront of material science, connecting research with real-world uses.

As we learn more about carbon aerogels, their possibilities grow. Future research will likely bring even more exciting uses.

Comparative Analysis with Other Aerogels

Aerogel materials are a key area in advanced materials science. Each type has unique properties and uses. Our analysis looks at carbon, silica, and polymeric aerogels to show their amazing abilities in materials research.

Exploring Structural Differences

Carbon aerogels stand out in many fields. They have a huge surface area of about 1250 m²/g20. This makes them great for advanced energy storage.

Their pores can hold up to 1.2 cm³/g20. This allows them to conduct electricity better than other aerogels.

| Aerogel Type | Surface Area | Key Applications | Unique Properties |

|---|---|---|---|

| Carbon Aerogels | 1250 m²/g | Energy Storage | High Electrical Conductivity |

| Silica Aerogels | 600-800 m²/g | Thermal Insulation | Excellent Heat Resistance |

| Polymeric Aerogels | 300-500 m²/g | Biomedical Engineering | Biodegradability |

Comparative Performance Characteristics

Silica aerogels are great for keeping things cool. Carbon aerogels are top for electrical conductivity. Polymeric aerogels are flexible and can break down naturally.

The carbonization process for carbon aerogels happens between 400 to 1000 °C20. This lets scientists fine-tune their structure.

- Carbon Aerogels: Optimal for energy storage

- Silica Aerogels: Best for thermal management

- Polymeric Aerogels: Ideal for flexible applications

Designing carbon materials should focus on using space well and getting to the core20. This helps scientists create more advanced uses for aerogels in different fields.

Conclusion: The Importance of Carbon Aerogels in Advanced Materials

Carbon aerogels are a major breakthrough in materials science. They offer new ways to solve big technological problems. We’ve seen how they can improve energy storage, manage heat, and help the environment21.

These materials are very light but strong. They have huge surface areas, from 500 to 3000 m²/g. This makes them very useful in many scientific fields21.

Scientists are always finding new ways to make carbon aerogels better. Research papers show how to make them stronger and better at carrying electricity21. They’re also working on making them flexible for use in electronics and energy storage.

The future of carbon aerogels looks bright. Scientists want to make them cheaper and more available. They’re looking at new ways to use them in things like renewable energy and cleaning up the environment.

Carbon aerogels show what advanced materials science can do. By combining new research, smart engineering, and a focus on big problems, scientists are opening up new possibilities. These could change how we use energy, take care of the environment, and innovate.

FAQ

What are carbon aerogels?

How are carbon aerogels manufactured?

What are the primary applications of carbon aerogels?

What types of carbon aerogels exist?

What are the key advantages of carbon aerogels?

What challenges exist in carbon aerogel production?

How do carbon aerogels compare to other aerogel types?

What are the future trends in carbon aerogel research?

What makes carbon aerogels unique in materials science?

Are carbon aerogels environmentally friendly?

Source Links

- https://pmc.ncbi.nlm.nih.gov/articles/PMC9370447/

- https://www.llnl.gov/article/48816/llnl-intern-fabricates-carbon-aerogel-structures-energy-storage-applications

- https://link.springer.com/article/10.1557/jmr.2017.411

- https://www.nature.com/articles/s41467-018-03268-y

- https://www.mdpi.com/2079-4991/12/18/3172

- https://www.cambridge.org/core/journals/journal-of-materials-research/article/gas-permeability-of-carbon-aerogels/AB9229B23CAEE4468A044C6179034276

- https://link.springer.com/chapter/10.1007/978-1-4615-2570-7_32

- https://pmc.ncbi.nlm.nih.gov/articles/PMC9504413/

- https://ipo.llnl.gov/technologies/chemicals-and-materials/advanced-carbon-aerogels-energy-applications

- https://ipo.llnl.gov/technologies/chemicals-and-materials/large-scale-production-carbon-aerogels-precursors

- https://patents.google.com/patent/US20100288160A1/en

- https://www.llnl.gov/article/36686/advanced-carbon-aerogels-energy-applications

- https://www.mdpi.com/2079-4991/12/15/2721

- https://pmc.ncbi.nlm.nih.gov/articles/PMC11202916/

- https://physicsworld.com/a/porous-carbon-aerogels-might-power-future-mars-missions/

- https://link.springer.com/article/10.1007/s10971-024-06455-0

- https://www.alfachemic.com/gels/what-is-carbon-aerogel.html

- https://www.mdpi.com/2077-0472/13/1/208

- https://www.globenewswire.com/news-release/2022/01/24/2371631/0/en/Global-Carbon-Aerogel-Market-is-Expected-to-Grow-at-a-CAGR-of-12-54-from-2021-to-2030-Quince-Market-Insights.html

- https://www.mdpi.com/2310-2861/10/6/389

- https://pubs.rsc.org/en/content/articlehtml/2021/ma/d0ma00087f