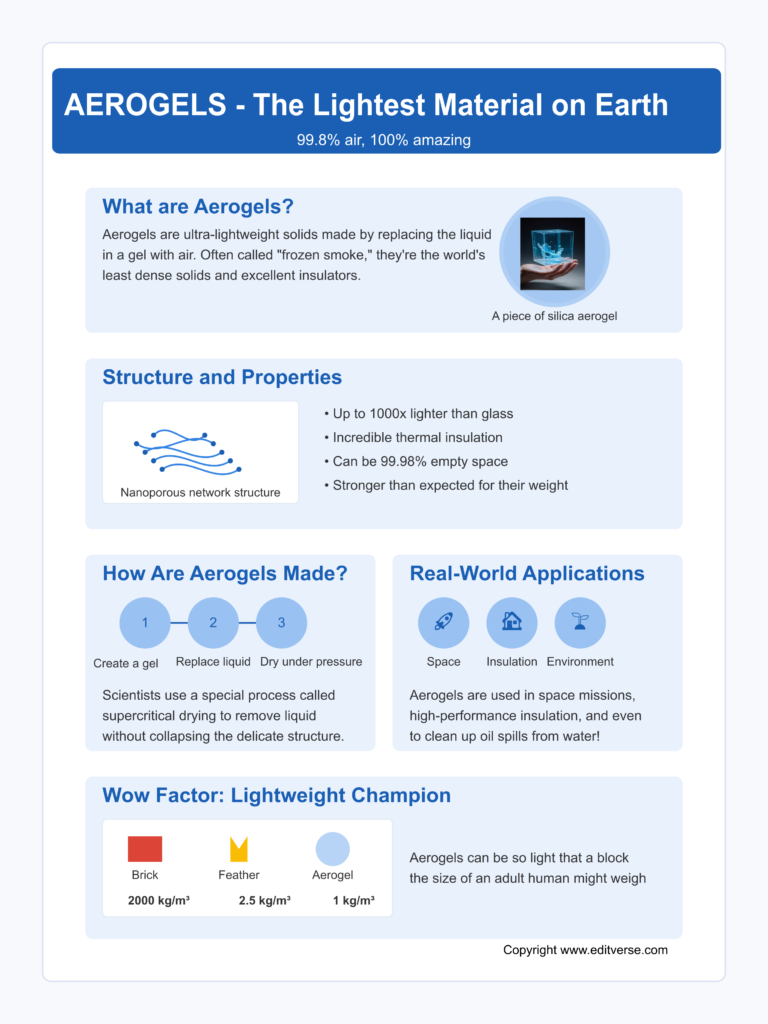

Imagine a material so light that a block the size of a person weighs less than a pound. Yet, it can hold about 1,000 pounds1. Welcome to the amazing world of aerogels, a new substance that changes how we see solid materials2.

What You Must Know About Aerogels – The Lightest Material on Earth

| Aspect | Key Information |

|---|---|

| Definition | Aerogels are ultra-low-density solid materials derived from gels where the liquid component has been replaced with gas without significant collapse of the gel structure. Often called “solid smoke” or “frozen smoke,” they are characterized by a nanoporous structure that can be composed of up to 99.8% air by volume, making them the lightest solid materials known to science. |

| Materials |

|

| Properties |

|

| Applications |

|

| Fabrication Techniques |

|

| Challenges |

|

Aerogels are a new class of super-light solids, with up to 99.8% air. They are the lightest solid material known to science2. These incredible substances, often called “frozen smoke,” have amazing properties. They have caught the attention of researchers and engineers all over the world3.

Our journey into aerogels will show how they are changing many industries. From aerospace to environmental uses, aerogel properties are breaking new ground in material science with amazing abilities.

Key Takeaways

- Aerogels are made of 99.8% air, making them very light

- A single block can hold up to 1,000 pounds, even though it weighs less than a pound

- First discovered in 1931 by Samuel Stephens Kistler

- Used in advanced fields from space exploration to keeping things warm

- They are a big step forward in material science

1. Introduction to Aerogels

Aerogels are a big deal in materials science. They are one of the most interesting synthetic substances ever made by NASA scientists. These materials are unlike anything we’ve seen before, challenging our ideas about solid structures4.

What Are Aerogels?

Aerogels are very light synthetic materials. They are mostly air, with 99.8% air by volume. This makes them incredibly light, with densities as low as 0.003 g/cm³ to 0.5 g/cm³45.

Types of Aerogel Composition

Aerogels come in different types, each with unique properties:

- Silica aerogels: They are clear and can handle heat up to 1,200 °C4

- Carbon aerogels: Great for keeping things cool5

- Polymer-based aerogels: They are flexible

Brief History of Aerogel Development

Aerogels have been around for over 80 years, with big leaps in recent years4. Samuel Kistler first made them in 1931. NASA has helped make them useful, turning them into materials with huge potential5.

Aerogels are a huge step forward in materials engineering, showing us what’s possible.

They have amazing features like:

- Surface area over 1000 m²/g4

- Pore sizes from 2 nm to 50 nm4

- Thermal conductivities as low as 0.013 W/m·K4

As we learn more about these materials, we see their potential in many areas, from space to environmental tech.

2. Key Properties of Aerogels

Aerogels are a new class of materials with amazing features. They are much lighter than air and have special properties. These make them stand out in science and industry6.

Physical and Chemical Composition

Aerogels are very light, with a density of 0.0011 to 0.5 g/cm³. This is much lighter than air6. They also have a nano-porous structure. This structure helps them insulate very well, with over 85% porosity6.

Exceptional Characteristics

- Ultra-low density material

- High porosity structure

- Extraordinary thermal insulation

- Large specific surface area

Scientists have found aerogels to be amazing. They hold 14 world records6. Their special make-up lets them catch fast particles and handle extreme conditions, like in NASA spacesuits6.

| Property | Characteristic |

|---|---|

| Density | 0.0011 – 0.5 g/cm³ |

| Porosity | > 85% |

| Thermal Conductivity | Extremely Low |

| Surface Area | Remarkably High |

The mechanical properties of aerogels vary with porosity. They can be studied from 0%-99% porosity7. Their elastic modulus and rupture strength can be changed by adjusting their chemical makeup7.

These amazing properties make aerogels a groundbreaking material. They have potential uses in insulation, aerospace, and advanced technologies6.

3. Types of Aerogels

Aerogels are a world of advanced materials with unique properties. They have many uses in science. These materials are key in many technologies8.

There are three main types of aerogels. Each has its own features and uses:

- Silica Aerogels: The most studied type8. They have very low heat conductivity and can be very light9.

- Carbon Aerogels: Great for electrical uses, like in fuel cells and supercapacitors8.

- Metal Oxide Aerogels: Used as catalysts and can have magnetic and colorful properties8.

Silica Aerogels: A Closer Look

Silica aerogels are special. They have a huge surface area and can be very transparent9. They also have a low dielectric constant, making them useful in tech9.

Carbon Aerogels: Electrical Pioneers

Carbon aerogels are known for their electrical properties. Some can stretch up to 80% of their original length9. This makes them great for engineering and electronics9.

Emerging Aerogel Technologies

New materials like x-aerogels and strong polymer aerogels are being developed. Companies like Aerogel Technologies are making Airloy® Ultramaterials. These advancements are pushing the limits of aerogels9.

4. Manufacturing Processes of Aerogels

Aerogel manufacturing is a blend of chemistry and materials science. It turns simple gels into amazing materials with unique properties.

Making aerogels is a complex process that needs precision and new tech. Scientists have found many ways to make these materials. Each method has its own special features and challenges.

Sol-Gel Process: The Foundation

The sol-gel process is key in making aerogels. It involves several important steps:

- Preparing liquid precursor solutions

- Creating a colloidal suspension

- Turning the suspension into a gel network

- Removing liquid carefully to keep the structure intact

Supercritical Drying: Preserving Structural Integrity

Supercritical drying is a game-changer in aerogel making. It lets scientists remove liquid from the gel without harming its structure10. Aerogels can be up to 99.8% air, making them very light10.

Innovative Drying Techniques

New drying methods are being tested in aerogel making. Researchers are looking into ambient pressure drying to cut costs. They want to make aerogel production cheaper11.

The future of aerogel technology looks bright, with big market growth expected11. As making techniques get better, we’ll see more uses of these amazing materials in different fields.

5. Mechanical Properties of Aerogels

Aerogels are a unique group of materials with amazing mechanical traits. They are very light but incredibly strong. This makes them a big interest in science12.

The strength of aerogel composites changes a lot based on what they are made of and how they are made. Scientists have found that making small changes can greatly improve their strength12.

Tensile Strength and Compression Resistance

Aerogels have special ways of behaving under stress. They are very light but can hold a lot of weight. They can even hold up to 4000 times their own weight12.

Mechanical Property Characteristics

| Property | Typical Value | Significance |

|---|---|---|

| Elastic Modulus | 0.042 GPa | Indicates material flexibility |

| Compressive Yield Stress | 0.023 GPa | Demonstrates load-bearing capacity |

| Mean Pore Size | 152.1 nm | Influences mechanical performance |

The strength of aerogels can grow by thousands of times as their density changes12. This makes them very useful for new engineering projects.

It’s interesting that tiny flaws can greatly affect their strength. This shows how complex and unique these materials are12.

6. Thermal Insulation with Aerogels

Aerogel insulation is a game-changer in thermal management. It has changed how we protect against heat in many fields. It offers top-notch heat prevention and boosts energy efficiency13.

Thermal Conductivity Insights

Aerogels have amazing thermal properties because of their nanoscale structure. They have a very low thermal conductivity of 0.02 W/(m·K) at 25°C. This is even lower than static air13. This makes aerogel insulation a top pick for advanced thermal management14.

Composition and Performance

Aerogels are mostly air with nano-sized pores, with about 97% air and 3% solid material14. Their unique structure offers great insulation:

- Extremely low thermal conductivity

- High porosity ranging from 80-99.8%13

- Specific surface area between 100-1400 m²/g13

- Ultra-low density from 0.003 to 0.4 g/cm³13

Aerogel Applications in Insulation

Aerogels are used in many areas, like industrial and commercial buildings. They help improve energy efficiency and make buildings thinner14. They are versatile and can be used in:

- Building insulation

- Aerospace thermal protection

- Industrial equipment shielding

- High-temperature resistant systems

Research and development in aerogel technology are growing. This makes aerogels a promising solution for solving thermal management challenges13.

7. Aerogels in Aerospace Applications

Aerogels are making waves in aerospace, exciting scientists and engineers globally. They play a key role in pushing space exploration forward through new material research.

Breakthrough in Space Exploration Technologies

Aerogel research shows great promise in harsh environments. NASA has led the way in using these materials for major breakthroughs15:

- Mars Rover Insulation: Aerogels keep rovers safe from extreme temperatures15

- Hypersonic Inflatable Aerodynamic Decelerator (HIAD) Project: Working on advanced heat shields15

- Polymer-based Aerogel Development: Making flexible, light insulation15

Thermal Protection Systems

Aerogels are perfect for keeping spacecraft cool. They are extremely light but insulate very well. With about 95% air, they’re top-notch thermal barriers16. Their heat transfer is very low, from 0.01 to 0.02 W·m⁻¹·K⁻¹16.

The future of aerospace material science is bright with aerogels. Scientists are finding new uses, like insulating space suits and building habitats on other planets15.

8. Aerogels in Environmental Applications

Environmental challenges need new solutions, and aerogels are showing great promise. Our aerogel research is finding ways to tackle big environmental problems17.

Oil Spill Cleanup Innovations

Aerogels are amazing at cleaning up oil spills. They can soak up oil but not water, which is a game-changer for the environment17.

- Selectively absorb oil while repelling water

- Capture up to 99% of oil contaminants

- Reusable and environmentally friendly

Air Filtration and Pollution Control

New aerogel tech is changing how we fight pollution. They can catch tiny particles and gases, making the air cleaner17.

Scientists are also looking at aerogels for trapping greenhouse gases. This could be a big step in fighting climate change. Their high porosity makes them super good at cleaning up the environment17.

Aerogels are a leading edge in protecting our environment, combining new materials with green solutions.

9. Challenges in Aerogel Production

The world of aerogel making faces big hurdles that slow down its use in the market. These main issues are the complexity of making aerogels and the high costs involved. These problems affect the aerogel market18.

Cost-Effective Manufacturing Barriers

Making aerogels is a detailed and expensive process. This makes it hard to make them on a large scale18. Some big challenges are:

- High energy use during making

- Need for special equipment

- Current methods can’t be scaled up easily

Scalability Limitations

Going from lab tests to big production is tough. Aerogels make up only 1.1–2.6% of the global thermal insulation market. This shows how hard it is to scale up19.

Scientists are working on new ways to solve these problems. They’re looking into:

- Ambient pressure drying methods

- Continuous production methods

- New ways to remove solvents

| Production Challenge | Current Limitation | Potential Solution |

|---|---|---|

| Cost | Expensive processing | Streamlined manufacturing |

| Scalability | Limited industrial production | Continuous production techniques |

| Material Quality | Inconsistent properties | Advanced quality control |

The future of aerogel making depends on solving these big challenges. By finding better, cheaper ways to make aerogels, scientists hope to grow the market. They want to use aerogels in many different fields18.

10. Future Trends in Aerogel Technology

The world of aerogel research is changing fast. New discoveries are set to change many industries. These materials are getting even more amazing, opening up new chances in many fields20.

The market for aerogels is growing fast. Big steps are being made in important areas:

- Electric Vehicle (EV) Battery Applications20

- Energy Storage Solutions21

- Industrial Thermal Insulation20

- Advanced Manufacturing Techniques

Innovations in Material Science

New aerogel research is all about making smart materials better. The global aerogel market hit almost US$450 million in 202221. It’s expected to grow by 12.2% each year from 2025 to 203520.

Potential New Applications

| Sector | Emerging Application |

|---|---|

| Automotive | EV Battery Fire Protection20 |

| Aerospace | Lightweight Thermal Insulation |

| Electronics | Flexible Sensing Technologies |

New things are happening with polymer and carbon aerogels. People are really interested in using them in new electric flying cars21. China is leading in making aerogels, making up about 97% of all production20.

The future of aerogel technology promises transformative solutions across multiple industries, driven by continuous innovation and expanding market potential.

11. Conclusion: The Future of Aerogels

Aerogel research has shown great promise in many fields. These materials have unique properties that make them key players in technology and engineering. They are very light, with densities from 0.003 to 0.500 g∙cm−3, and are up to 99.8% porous22.

The global aerogel market is growing fast. It’s expected to see big increases in the next few years. In 2018, Asia-Pacific led the market with 52.2% share23. Experts predict the market will hit about 2 billion USD by 2028, thanks to new uses in space, the environment, and advanced manufacturing.

Our look into aerogel technology shows a lot of room for growth. Aerogels made from materials like silica and alumina have huge surface areas, from 325 m²/g to 450 m²/g24. These findings suggest aerogels could lead to big advances in keeping things warm, making things lighter, and green technologies.

Looking ahead, scientists must keep exploring aerogel possibilities. We need to solve production problems to fully use these materials. The future of aerogel research holds many exciting discoveries that could change many industries.

FAQ

What exactly are aerogels?

Who discovered aerogels and when?

What makes aerogels so unique compared to other materials?

What are the main types of aerogels?

How are aerogels manufactured?

What are the primary applications of aerogels?

What challenges exist in aerogel production?

What are the future trends in aerogel technology?

Are aerogels environmentally friendly?

How do aerogels perform in extreme environments?

Source Links

- https://www.azom.com/article.aspx?ArticleID=19428

- https://www.americanscientist.org/article/like-holding-a-piece-of-sky

- https://earthlymission.com/aerogel-graphene-worlds-lightest-material-99-percent-air-solid-substance/

- https://www.cambridge.org/core/books/chemistry-and-physics-of-aerogels/introduction/4370A93C76BF6EDB1FE17BF27D81E1F6

- https://pmc.ncbi.nlm.nih.gov/articles/PMC10754877/

- https://www.azom.com/article.aspx?ArticleID=6499

- https://www.mdpi.com/2310-2861/1/2/256

- https://www.scienceabc.com/pure-sciences/what-is-the-lightest-material-yet.html

- https://www.aerogeltechnologies.com/what-are-aerogels/

- https://www.azobuild.com/article.aspx?ArticleID=8656

- https://www.energy.gov/eere/buildings/articles/innovative-aerogel-production-low-cost-and-high-r-insulation

- https://pmc.ncbi.nlm.nih.gov/articles/PMC6318623/

- https://pmc.ncbi.nlm.nih.gov/articles/PMC10453839/

- https://thermtest.com/application/aerogel-thermal-conductivity-hfm

- https://www.nasa.gov/aeronautics/aerogels-thinner-lighter-stronger/

- https://www.mdpi.com/2310-2861/7/4/264

- https://www.mdpi.com/1996-1944/8/10/5343

- https://interestingengineering.com/innovation/aerogel-the-futuristic-material-hindered-by-real-world-limitations

- https://www.mdpi.com/journal/gels/special_issues/9AEFN4LP94

- https://www.idtechex.com/en/research-report/aerogels-2025-2035-technology-market-forecasts/1076

- https://www.idtechex.com/en/research-report/aerogels/954

- https://pmc.ncbi.nlm.nih.gov/articles/PMC6403747/

- https://pmc.ncbi.nlm.nih.gov/articles/PMC10058649/

- https://www.frontiersin.org/journals/chemistry/articles/10.3389/fchem.2023.1294520/full